JA-180G

Service explanation for JA-180G

Gas leak detector

The JA-180G detector ensures the timely detection of leakage of flammable gases (natural gas, light gas, propane, butane) and flammable vapours. The detector is powered directly from the el. mains powered, signals gas leakage optically, acoustically and also transmits information via Jablotron radio protocol.Installation

The detector is intended for installation in areas without significant danger - e.g. residential, light industrial or boiler rooms.

We recommend that the installation be carried out in accordance with EN 50244 and by a person with the required electrical engineering qualification!

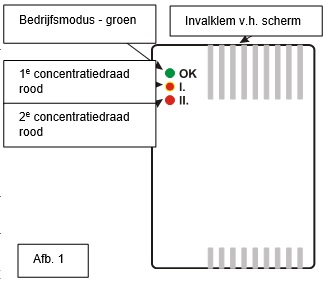

Open the detector's cover by pressing the snap clip on the side and fix the back part of the housing with the electronics panel in the chosen place using screws. Install the lighter-than-air (natural gas) detector near the site, above the possible leakage of the gas, on the wall, a maximum of 15 cm below the ceiling or directly on the ceiling. Install the heavier-than-air (propane) detector close to the floor or at the lowest point of the room/room. Always position the detector so that the entry and exit openings in the detector screen face the assumed direction of airflow.

Never install the detector near obstacles that impede natural air circulation, in places where there is a lack of oxygen and in places where the operation of the detector may be affected by various odors (stench) or vapor condensation (e.g. near of a stove). A strong air current in the vicinity of the detector can also have a negative influence on the detection.

Connect the supply conductors, set the internal switches, close the detector screen, put the control panel (receiver) in learning mode and finally power up the detector.

Clamping the power supply

Power supply from the mains is connected to the terminals marked 230V AC. The connection is via a fixed supply cable. Before turning on the power, check the connection and close the detector screen. Never open the detector with the power on.

Terminals of the relay

Switching contacts of the output relay are routed to the terminals as follows:

C common contact

NO make contact

NC NC contact

The output of the relay can be used for automatic shut-off of gas supply via an electric valve, for external signaling of danger, etc.

ATTENTION: The mains output of the relay does not cause safety disconnection!

Internal switches

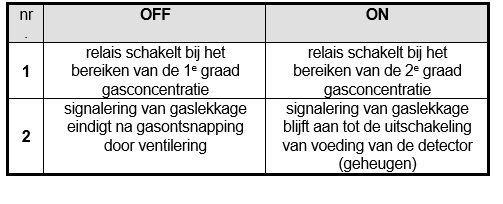

There are two setting switches in the detector:

no. OFF ON

1 relay switches when the 1st degree gas concentration is reached relay switches when the 2nd degree gas concentration is reached

2 gas leak signaling ends after gas escape by venting gas leak signaling remains on until the detector is powered off (memory)

Function

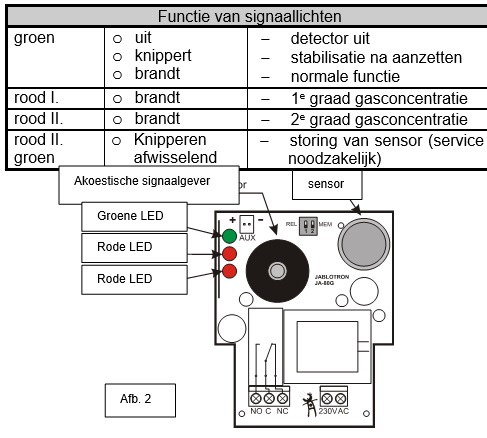

After switching on the power supply, the detector sends a learning signal to the control panel (receiver) and the green signal light starts flashing (for approx. 90 sec. - detector is stabilizing). Then a short beep sounds and the green light stays on continuously, that means the sensor is ready to work.

When the concentration of the leaking gas reaches the value of the 1st degree sensitivity, short audio signals will sound and the red light I. will light up.

If the gas concentration exceeds the 2nd degree sensitivity, long audio signals will sound and the red light II. light up.

The fact at which gas concentration the relay will react is determined by internal switch no. 1.

The alarm signal (Fire type) is sent by the detector at the moment of relay activation (ie the transmission is affected by setting of internal switch #1).

The JA-180G detector does not check the connection to the control panel (receiver), i.e. the system does not report detector loss in case of detector power failure.

CAUTION – if a gas leak is indicated, prevent a fire (ignition) in this area (do not use electrical switches, ventilate thoroughly, stop gas leak, call fire brigade or gas supplier if necessary).

Maintenance and informative function check

Keep the appliance clean and check occasionally whether the grille of the lid is permeable, if necessary clean it by carefully blowing away the dust.

Detector response can be tested using a cigarette gas lighter (without flame). The expert calibration of the detector is done by the manufacturer, it is recommended at the latest 1 year after commissioning.

Technical parameters

Power supply from the mains 230V (+10 to -15%) / 50Hz, approx. 2W, prov. class II

Loud alarm 94 dB / 0.3 m

Relay output optional response to 1st or 2nd degree

Load capacity relay switching contact max. 230 V / 5 A

Working temperature -10 °C to +40 °C

Relative humidity 25 to 75%

Warm-up time after switching on approx. 90 s

Response time up to 10 s

Method of detection catalytic oxidation

Protection IP 30 ( EN 60 529 )

Communication band 868.1MHz, Jablotron protocol

Communication range approx. 200m on direct visibility

Dimensions, weight 101 x 74 x 39, 210 g

Constructed for operation in normal atmospheric pressure ie 86 to 106kPa

Complies with EN 61779-1, EN 61779-4, EN 50130-4, EN 55022, ETSI EN 300220, 60950-1

Intended for environment without major hazard BE 1 (2000-3)

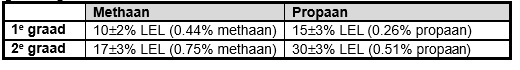

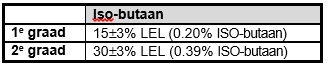

Sensitivity:

Note: LEL = Lower Explosive Limit, calibrated by iso-butane

The product has been designed and manufactured in accordance with the applicable provisions: Government Decree No. 426/2000 Coll., provided that it is used according to its intended purpose.

Note: Although this product does not contain any harmful materials, do not dispose of it with household waste, but hand it in at the collection point designated for electronic waste.