JA-110B

Service explanation for JA-110B

Wired glass break detector

This product is part of the JABLOTRON JA-100 alarm system. It serves to detect the breakage of glass panels, which are part of the shell of the building to be protected. It responds to air pressure change, which is accompanied by the characteristic sound of glass breaking. The detector has an impulse response (it only reports its own activation). The product is intended for assembly by a trained technician with a valid Jablotron certificate.

Installation

The detector is mounted in the interior. There must be no sound/noise sources, no vibrating devices and/or moving objects that generate a pressure wave in the room to be monitored. We also advise against mounting the detector where the air flows (ventilation, air conditioning, drafts, non-closing doors, etc.). There may be no sound-absorbing objects in front of the detector (e.g. thick curtains).

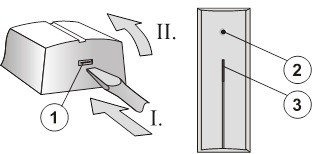

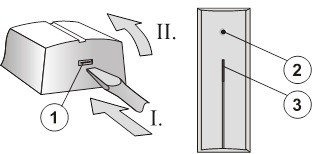

Figure: 1 – hood snap clip; 2 – sensors; 3 – activation and fault indicator lights;

1. Open the hood by pressing the snap clip (1)

2. Remove the electronics board – by loosening the snap clip (5).

3. Pull the cables through the plastic back wall and screw them in place.

Before connecting the BUS, the system must be disconnected from the power supply.

4. Replace the electronics and connect the bus cable to the terminals (6).

5. Follow the installation manual of the control panel. Basic Steps:

a. After switching on, the yellow signal light (9) flashes because the detector is not assigned to the system.

b. Select the desired position in the F-Link program on the Peripherals card and start the learning mode with the Read button.

c. Press the tamper switch in the detector (11) - this will teach the detector and the yellow signal light will go out.

6. Close the detector cover and check that the rubber part of the sensor (4) does not cover the hole in the cover.

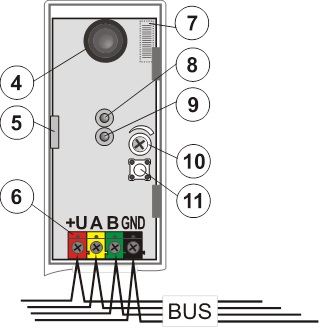

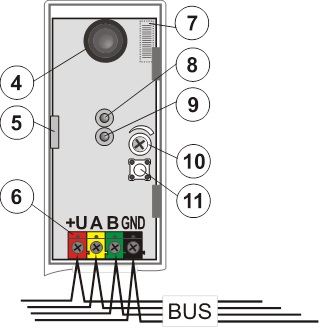

Image: 4 – sensor; 5 – electronics snap clip; 6 – terminals for the bus; 7 – barcode (placed from below); 8 – detector activation red signal light; 9 – yellow fault indicator light; 10 – sensitivity setting; 11 – tamper switch;

Test and set detector

Strike successively with a suitable tool or by hand in a protective glove against all glass surfaces in the monitored area (the glass must not break, only deform). The detector reacts to the deformation of the glass (change of pressure in the chamber) by briefly flashing the red signal light. The reaction should only come after a clear blow against the glass.

Sensitivity to pressure changes can be set with the trimmer (10). Sensitivity set too high can cause false alarms.

Complex operation of the detector can be checked by the GBT-212 test, which generates the sound of breaking glass after a blow against the glass. In that case, the red signal light of the detector (8) will light up for 3 seconds.

Turn off signal light

This is done by the F-Link program – Card Peripherals. Select the Internal settings at the position of the detector. A dialog appears, in which the signal light of the detector activation (8) can be turned off.

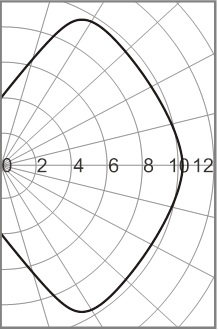

Detection characteristic

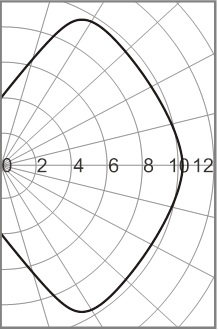

Image: Detection characteristic of the detector.

Technical parameters

Power supply from the control panel BUS 12 V (9 ... 15 V)

Current consumption at stand-by (rest) 5 mA

Current consumption for choice of cable 5 mA

Recommended installation height 2.5 m above the floor

Detection distance up to 9 m

Minimum surface of the glass panel 0.6 x 0.6 m

Period of stabilization after switching on: max. 60 s

Dimensions 40 x 100 x 22mm

Classification grade 2

in accordance with CSN EN 50131-1, CSN CLC/TS 50131-2-7-1

Environment in accordance with CSN EN 50131-1 II. inside, general

Operating temperature range -10 to +40 °C

Further complies with CSN EN 50130-4, CSN EN 55022

Installation

The detector is mounted in the interior. There must be no sound/noise sources, no vibrating devices and/or moving objects that generate a pressure wave in the room to be monitored. We also advise against mounting the detector where the air flows (ventilation, air conditioning, drafts, non-closing doors, etc.). There may be no sound-absorbing objects in front of the detector (e.g. thick curtains).

Figure: 1 – hood snap clip; 2 – sensors; 3 – activation and fault indicator lights;

1. Open the hood by pressing the snap clip (1)

2. Remove the electronics board – by loosening the snap clip (5).

3. Pull the cables through the plastic back wall and screw them in place.

Before connecting the BUS, the system must be disconnected from the power supply.

4. Replace the electronics and connect the bus cable to the terminals (6).

5. Follow the installation manual of the control panel. Basic Steps:

a. After switching on, the yellow signal light (9) flashes because the detector is not assigned to the system.

b. Select the desired position in the F-Link program on the Peripherals card and start the learning mode with the Read button.

c. Press the tamper switch in the detector (11) - this will teach the detector and the yellow signal light will go out.

6. Close the detector cover and check that the rubber part of the sensor (4) does not cover the hole in the cover.

Image: 4 – sensor; 5 – electronics snap clip; 6 – terminals for the bus; 7 – barcode (placed from below); 8 – detector activation red signal light; 9 – yellow fault indicator light; 10 – sensitivity setting; 11 – tamper switch;

Test and set detector

Strike successively with a suitable tool or by hand in a protective glove against all glass surfaces in the monitored area (the glass must not break, only deform). The detector reacts to the deformation of the glass (change of pressure in the chamber) by briefly flashing the red signal light. The reaction should only come after a clear blow against the glass.

Sensitivity to pressure changes can be set with the trimmer (10). Sensitivity set too high can cause false alarms.

Complex operation of the detector can be checked by the GBT-212 test, which generates the sound of breaking glass after a blow against the glass. In that case, the red signal light of the detector (8) will light up for 3 seconds.

Turn off signal light

This is done by the F-Link program – Card Peripherals. Select the Internal settings at the position of the detector. A dialog appears, in which the signal light of the detector activation (8) can be turned off.

Detection characteristic

Image: Detection characteristic of the detector.

Technical parameters

Power supply from the control panel BUS 12 V (9 ... 15 V)

Current consumption at stand-by (rest) 5 mA

Current consumption for choice of cable 5 mA

Recommended installation height 2.5 m above the floor

Detection distance up to 9 m

Minimum surface of the glass panel 0.6 x 0.6 m

Period of stabilization after switching on: max. 60 s

Dimensions 40 x 100 x 22mm

Classification grade 2

in accordance with CSN EN 50131-1, CSN CLC/TS 50131-2-7-1

Environment in accordance with CSN EN 50131-1 II. inside, general

Operating temperature range -10 to +40 °C

Further complies with CSN EN 50130-4, CSN EN 55022